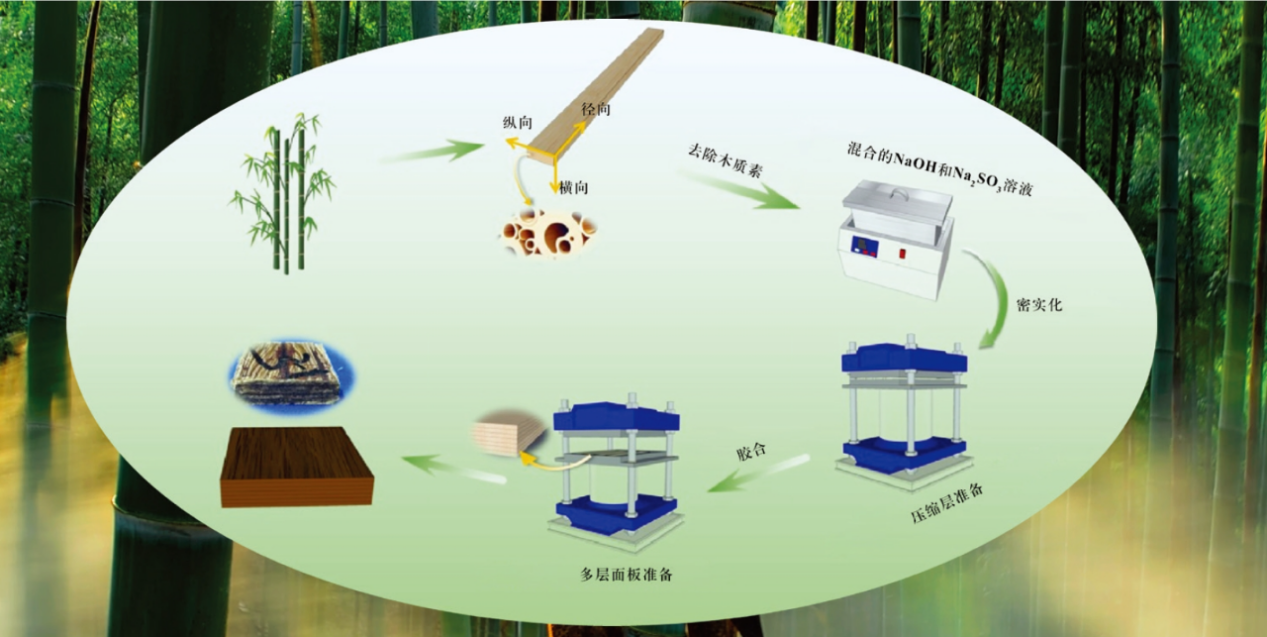

Fire safety in modern timber structures has been a growing concern, especially since the high thermal conductivity of metal fasteners can accelerate charring of wood during fires, thereby compromising the fire resistance of the entire structure. Against the backdrop of global climate change and energy shortages, bamboo, as a sustainable material, holds significant potential for structural applications. Research has shown that by physically and chemically modifying bamboo—removing lignin and hemicellulose while retaining its original fiber orientation and hierarchical structure, followed by hot-pressing treatment—its mechanical properties can be significantly enhanced. Although high-strength bio-based materials show great promise as alternatives to metal fasteners, there remains a lack of research on their performance and reliability under extreme high-temperature conditions. To address this, Chinese researchers have developed an environmentally friendly, high-performance, composite-modified bamboo plywood, providing a metal fastener alternative for sustainable construction and offering a scientific foundation for high-value bamboo applications and the advancement of green building materials.

Mechanical testing of the composite-modified bamboo plywood revealed significant improvements in the flexural modulus, flexural strength, and tensile strength of bamboo. Compared to natural bamboo, the composite-modified bamboo plywood subjected to 12 hours of alkaline treatment exhibited a 1.8-fold increase in flexural modulus, a 2.2-fold increase in flexural strength, and a 1.7-fold increase in tensile strength. Additionally, with increased alkaline treatment time, its ductility improved, indicating that the material can maintain a certain degree of plastic deformation while preserving its strength. Thermal stability analysis showed that the limiting oxygen index of the composite-modified bamboo plywood increased with the modification time, indicating enhanced fire resistance and reduced flammability in air. Combustion behavior testing using a cone calorimeter revealed that the composite-modified bamboo materials demonstrated superior flame retardancy and thermal stability compared to untreated bamboo. Dynamic mechanical analysis further showed that the modification treatment reduced internal voids and molecular motion within the bamboo, thereby decreasing damping behavior and increasing the glass transition temperature. The hot-pressing process preserved the integrity of the cell walls, resulting in excellent interfacial interaction and stress transfer in the composite-modified bamboo material.

This post is republished from the International Bamboo and Rattan Organization (INBAR).

Preparation Process of Composite-Modified Bamboo